JWB series automatic folder glue machine

JWB series automatic folder glue machine

1.Machine introduction:

- The feeding unit adopts auto lead edge feeder. Side baffle can pat the corrugated paperboard.

- The gluing wheel is made of the stainless steel. Gluing pump supply the glue automatically. Glue less alarming and automatic cycle when the machine stops. Easy to be cleaned.

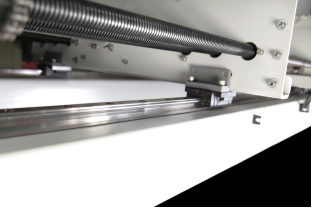

- Upper and down carrier moved by liner guide rail and motorized controlling.

- The pre-creasing wheels are install for the second creasing line.

- The final folding unit adopts the servo motor driving for the precision folding.

- The swing mode of stitching head. The machine can be gluing or stitching.

- The stitching can be single stitching, double stitching, double-single-double stitching.

- One switch changing for the gluing or stitching. The stitching head cab be move lift up when the machine works for the gluing.

- The all belts can be easy to be changed.

- PLC programs and 200 orders memory.

2.Technical Data

| Model | JW(B)-2400 |

| Max gluing speed | 200m/min |

| Max sheet size | 2400 x 1200 |

| Min sheet size | 600 x 300mm |

| Folding mode | up folding |

| Available sheet | 3 layer, 5layer |

| Adhesive | PVA |

| Total power | 36kw |

| Voltage | 380V, 50HZ, 3phase |

| Dimension | 15000 x 3400 x 2200mm |

| Weight | 15T |

3.Feeding unit

- Automatic lead edge feeder with 4 shafts.

- Side baffle can pat the corrugated paperboard and ensure the feeding precision.

- Automatic lead edge feeder with shafts.

4 . Automatic pump gluing system

- Automatic pump gluing system.

- Automatic cycle when machine stops and easy to be clean.

- Motorized movement for the glue tank.

5.Folding unit

- All down carrier are motorized movement.

- Upper creasing wheels to ensure the second creasing. It is 4 pieces and driving by motor.

- Upper and down carrier moved by liner guide rail.

- Servo motor driving for the outer belts to ensure the folding precision.

- Independent frequency inverter motor driving for the final folding unit

6.jector & Counter

7.Line guide rail

Down and upper carriers are line guide rail with motorized adjusted.

8.Configuration list

| Name | Brand |

| All servo driving motor | YASKAWA-Japan |

| All servo pack of driving motor | YASKAWA-Japan |

| All frequency inverter motor | CPG-Taiwan |

| All motor inverter controller | DELTA -Taiwan |

| PLC main touch screen | KINCO-Sino Germany |

| PLC programs | FATEK-Taiwan |

| Intermediate relay apparatus | OMRON-Japan |

| Main low voltage apparatus | ABB-Switzerland |

| All breaker | SCHNEIDER- France |

| Bearings | C&U-China, NSK-Japan, |