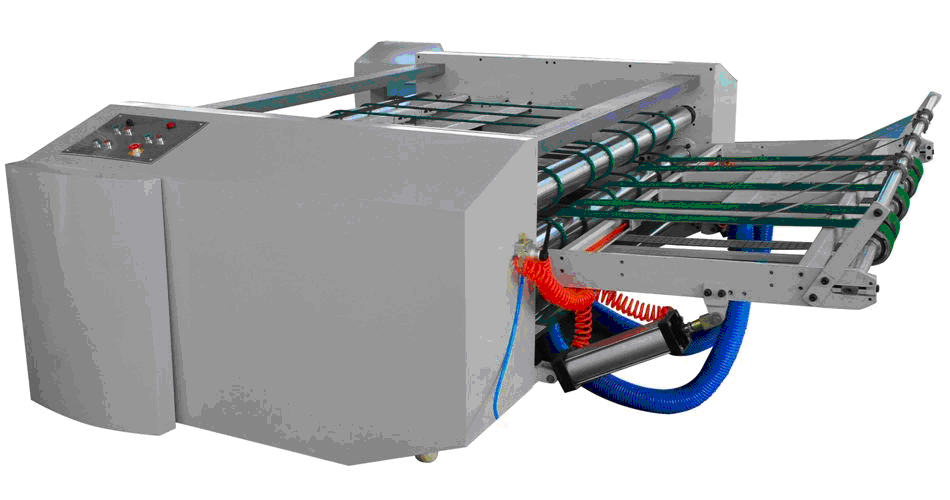

SQM Automatic rotary diecut machine

SQM Automatic rotary diecut machine

Model: 2000×1200, 2000×1400, 2200x 1200, 2200x 1400, 2400x 1200mm (Optional)

Rotary Die -Cut

Main function

The machine adopts light, electric, air and hydraulic combined control, safe and efficient. It can be finished slotting, corner cutting, slitting, creasing and handle in single process. It is especially suited for special-shaped box.

It adopted servo lead edge feeding system (Bosch Rexroth, German), die-cutting precision ±0.5mm.

The gears are on the processes of high frequency heat treatment, surface hardening and grinding, it is equipped with automatic spray lubrication, which greatly improves the running accuracy and service life.

The left and right baffle is adjusted by PLC control and touch screen display, fast and accuracy. Rollers adopt high quality steel, the inner quenched and tempered surface is grounded and balanced to improve the operation stability

Anvil cover is imported from USA, install and change quickly and conveniently, smooth cutting quality. Anvil covers life is 12 million times.

Lateral movement of die cutting roller adopt hydraulic device, the distance is 40mm, and also equip with auto recovery device, increased using life.

It using speed difference device without operator intervention, and automatic adjust roller speed, ensure that each batch of carton size fully consistent.

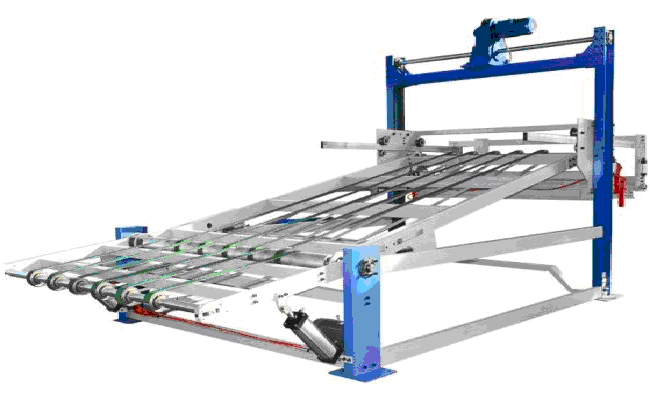

Vibration Waste Clean & Stacker

- It is Introduced foreign advanced experience, better to separate the waste from the finished products after die cutting,

- Beat and blow at the same time, completely remove waste, improve working conditions and efficiency.

- Receiving arm can be operated in manual or automatic mode

- Belt of receiving arm can be independently adjusted tightness.

- The platform lift is drove by the strong chain with safety devices to avoid slipping

- Stacking height is 1600mm

- The carrier plate is pneumatic driven. The carrier plate will pop-up and hold the coming carton sheet automatically when the pre-set height arrives.

- The motor of the platform lift is equipped with the brake, fix the platform and not slip back.

Main parts come from:

| Description | Origin |

| Servo Transmission motor | German Rexroth |

| Main motor | China |

| Anvil repair motor | China |

| Servo controller | German Rexroth |

| Inverter | Delta |

| PLC | Delta |

| Roll | China Sichuan |

| Wall | China Jiangsu |

| Gear | China Jiangsu |

| Anvil | USA |

| Transmission wheel | Taiwan |

| Pneumatic device | China Shanghai |

| Electric component | schneider |